6.3. STRAIGHT AIRBRAKE

The simplest form of airbrake is the system that is activated by a charge of air from the locomotive

straight to the brake cylinder of each car. Air is compressed and held in the supply reservoir of the locomotive.

Through a control valve in the locomotive cab, compressed air is piped directly to the brake cylinder of each

car. The air pressure on the braking apparatus can be maintained, and by exhausting the air, the brakes can be

released. The air compressor on the locomotive must recharge the reservoir after each prolonged application of

the brakes. This system is now obsolete and is rarely used in the United States except on some electric railway

cars and automotive trucks and buses.

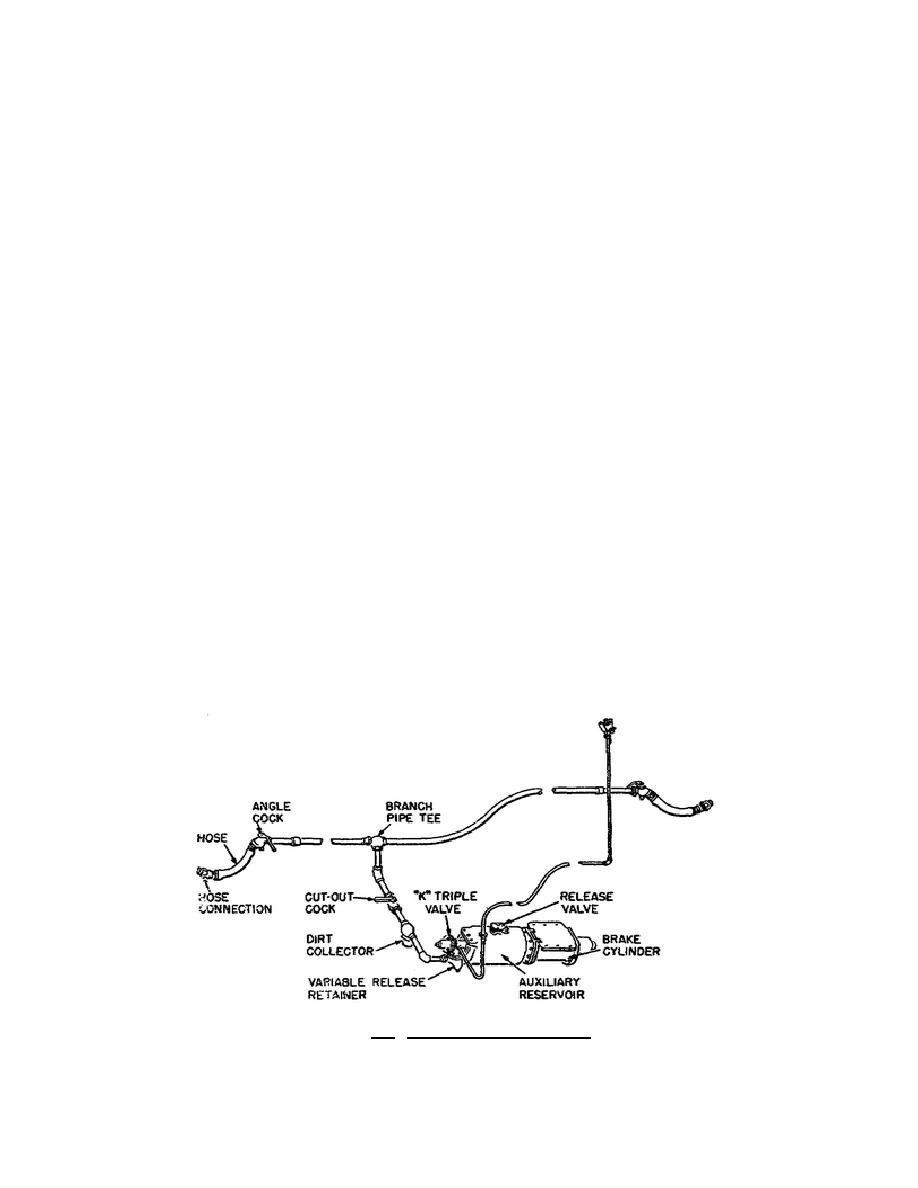

6.4. THE KC AIRBRAKE

Although the KC airbrake system, diagramed in figure 6.1, is no longer accepted in interchange service in

the United States, much of the Army-owned rolling stock for oversea use is equipped with it. The system has a

brake cylinder attached directly to an auxiliary reservoir under each car. A pipe running through the body of

this reservoir connects the brake cylinder to the KC triple valve that is connected to the opposite end of the

reservoir. Actually, the valve has three pipe connections: one to the brake cylinder, one to the auxiliary

reservoir, and one to the branch pipe. The valve operates in one of three ways in response to increases and

decreases of air pressure in the branch pipe: it charges the auxiliary reservoir by opening the line to it from the

branch pipe; applies the brakes by allowing the compressed air stored in the auxiliary reservoir to flow into the

brake cylinder; and releases the brakes by allowing the air in the brake cylinder to escape to the atmosphere.

Figure 6.1. The KC Airbrake System.

74

Previous Page

Previous Page