a. Burnt journal (AAR symbol 84). Any burned depression or continuous streak on the surface metal of

the journal or wheel seat may cause the axle to break or cause a hot journal, known as a "hotbox." An axle with

this defect must be removed from service and turned on a lathe. If the defect can be removed without reaching

the wear limits, the axle may be returned to service. If any wear limit given in tables II, III, or IV, is reached or

exceeded, the axle is scrapped.

b. Bent axle (AAR symbol 84-A). All second-hand axles should be checked in the lathe for roundness,

concentricity, and taper of wheel seats and journals after they have been dismounted. If they are bent, they

should be scrapped unless the wheel seats and journals can be trued within the prescribed limits.

c. Broken axle (AAR symbol 85). Any circumferential laps or seams in any portion of the axle can cause

it to break. A broken axle or one with a broken end collar must be scrapped.

d. Back journal fillet (AAR symbol 85-B). The back journal fillet should have the same radius as the

standard radius for a new axle; however, when the fillet is worn it should be restored to the original radius

unless in doing so the journal would exceed the length limits and require the axle to be scrapped. The AAR

rules permit the use of secondhand axles with minimum back fillet radii of 1/8 inch for A axles, 5/16 inch for B

axles, and 3/8 inch for C through F axles. The wheel-defect gage shown in figure 2.3 is used to measure the

back journal fillet.

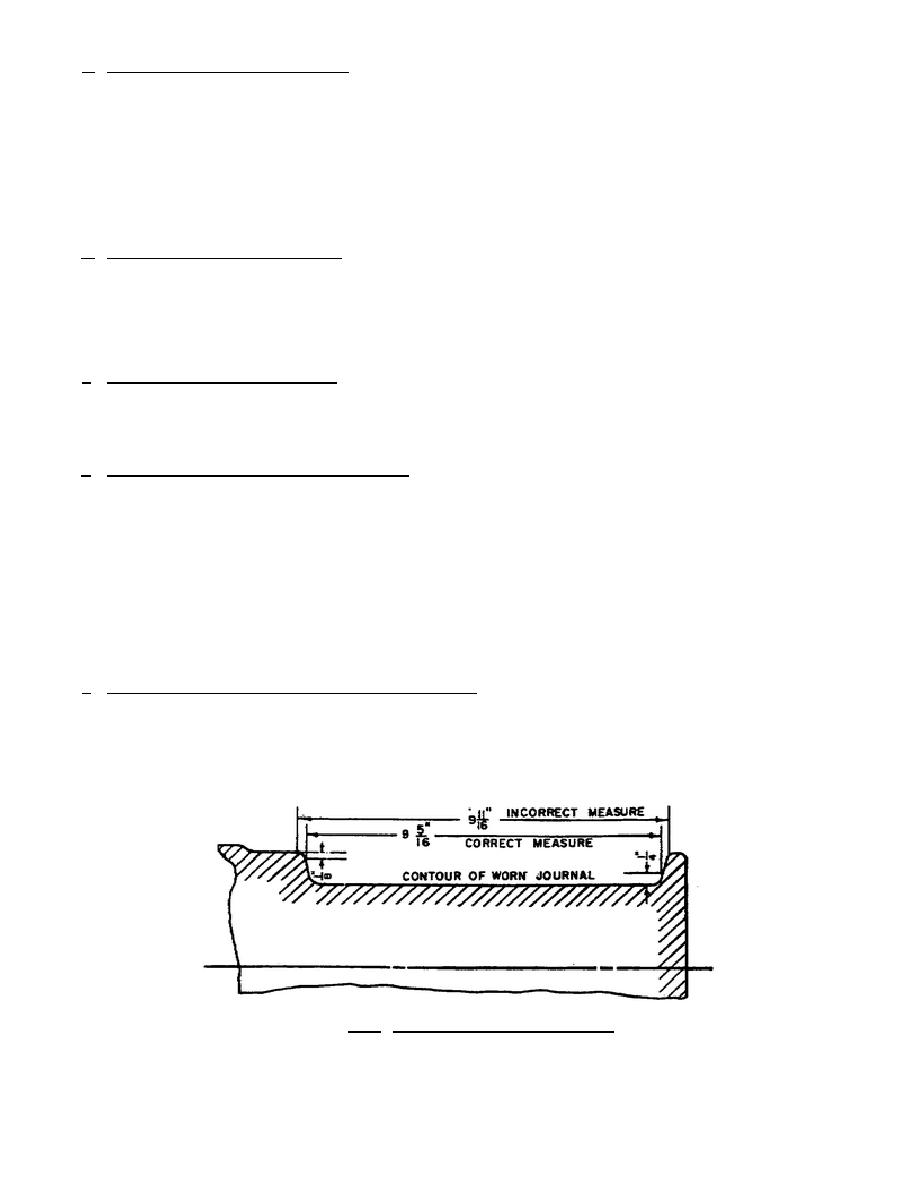

e. Journal length worn to limit (AAR symbol 85-C). Figure 2.25 shows how to measure the length of a

worn journal, and figure 2.26 shows the gage most commonly used to measure this defect. When the length of

the journal measures 11/16 inch more than the original length of the journal on an axle A through F, the axle

must be removed from service. Axles are usually scrapped because

Figure 2.25. Measurement of Worn Journal.

37

Previous Page

Previous Page