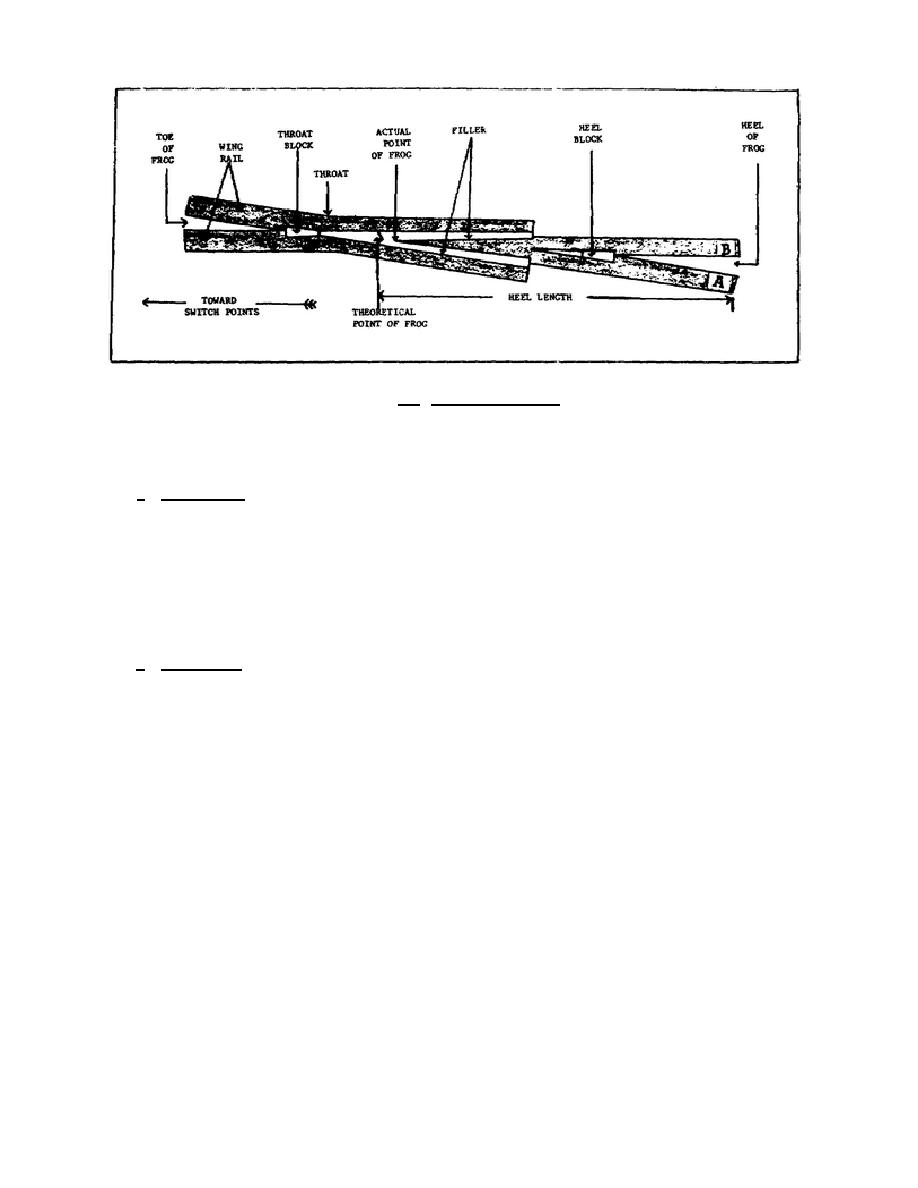

Figure 2.6. Frog Nomenclature.

is where the running rails are spliced to the frog. The primary classifications of frogs are the spring and rigid

types.

a. Spring frogs provide a smooth, uninterrupted path through the turnout in one direction. The flanges

of wheels passing over the alternate path force the wing rail of the frog open against spring tension. After the

train has passed through the turnout side, the springs force the wing rail back against the running rail, maintaining

the original route for main-line movements. Figure 2.7 shows the operation of this type of frog. The only

justifiable location for spring frogs is in turnouts where traffic is considerably heavier in one direction than in the

other and where it would not be desirable to delay movements through the little-used route. A main-track spring

frog is pictured in figure 2.8, in which the upper arrow points to the wing rail and the lower to the spring

mechanism.

b. Rigid frogs are divided into three groups: bolted-rigid, hard-centered (manganese insert), and

manganese-steel; all three are illustrated in figure 2.9. A rigid frog installed in track is shown in figure 2.10. The

bolted-rigid type is manufactured from standard rail sections cut as required and bolted together. It is standard

military stock and is issued as a unit. Hard-centered frogs have manganese-cast points attached to standard rail

sections. Since the point gets the greatest wear, it is made of extremely hard steel and is replaceable. The

manganese-steel type is of hard steel and cast in one piece. Since manganese-steel and hard-centered frogs have

greater resistance to wear, they are preferable to the bolted-rigid type, especially on main-line tracks and in busy

yards. The latter

36

Previous Page

Previous Page