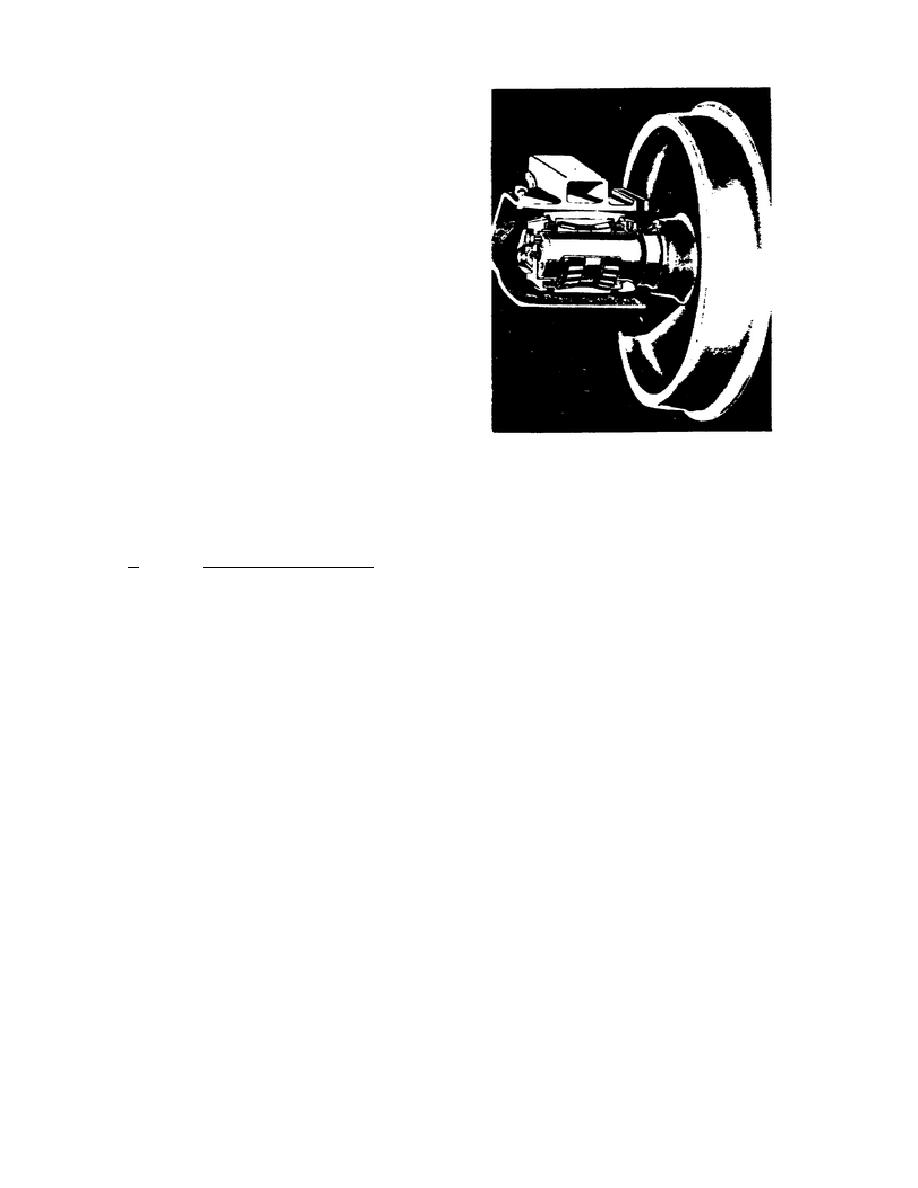

Journal roller bearings are

being used to a great extent

worldwide on both passenger and

freight

cars.

Because

these

bearings have sealed lubrication

units, they can run for 3 years

without

requiring

any

added

lubricant.

Also, they have almost

totally

eliminated

'hotbox"--

overheated

journal--problems,

provide better riding qualities for

the car, and lessen wheel and truck

wear.

Two general types are in

use: cylindrical and tapered hard

steel bearings fitted snugly to the

axle journal.

The tapered bearing

is shown in the insert.

3.5. COUPLERS

Railway cars are connected and disconnected by a coupler.

In the

continental United States (CONUS) and some foreign countries, the automatic

coupler is used; some other foreign countries use the hook-and-link coupler.

Both types are described in the subparagraphs following.

a. The automatic coupler, shown in figure 3.4, is best described as a

rotating hook. It is automatic only to the extent that it couples cars when

they are moved into contact with each other; it must be uncoupled manually.

The main parts of the automatic coupler are the head, knuckle and pin, and

shank.

(1) The head of the coupler has guard arms on which alining wings are

mounted.

This apparatus alines the coupler knuckles of opposing cars and

positions them for coupling.

(2) The knuckle and pin are the moving parts of the coupler that

perform the coupling action. Shaped like a hook, the knuckle rotates on a

pin; once it has rotated to the closed position, a block drops into place to

hold it closed:

(3) The shank is a continuation of the head providing a connection

with the draft gear. The shank transmits shock and pulling stress to the

draft gear which distributes them to the underframe of the car.

44

Previous Page

Previous Page