of trains operating over the track but must be long enough to prevent sudden jolts. Shims are available in varying

thicknesses and materials; those made of oak are best. Part C of figure 4.10 lists the dimensions of standard

shims. For thicknesses up to 1 inch, ordinary 5 1/2-inch spikes may be used to fasten the rail. For greater

thicknesses, 6- or 6 1/2-inch spikes must be used. The maximum thickness recommended is 2 to 3 inches.

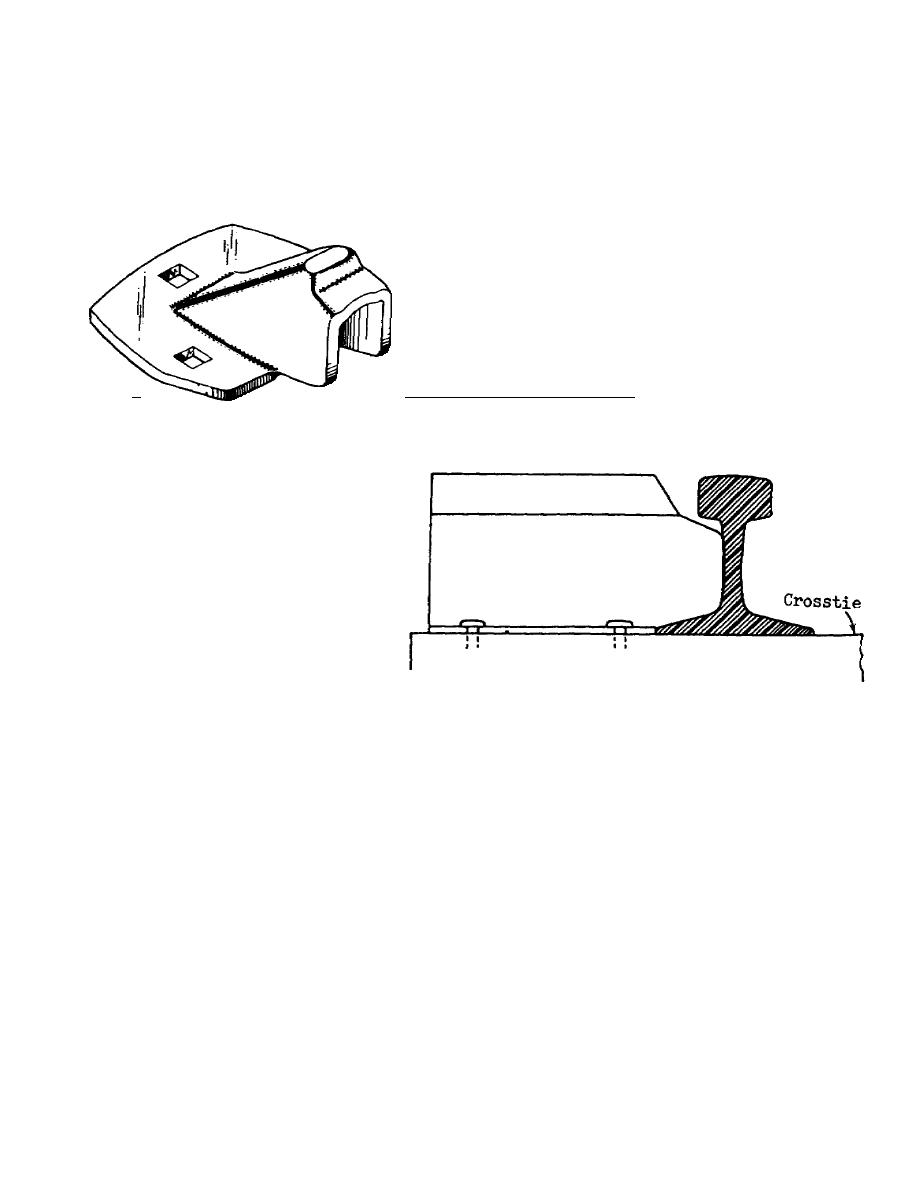

Part B of figure 4.10 illustrates seven ways to shim heaved track; overhead and vertical views of each

method are given. Note the rail braces used with the shims in views B(1), B(5), and B(6). Either metal or

wooden

bar

braces may be used. A metal one is shown in the sketch at the left; a wooden one is

shown in

view B(8) of figure 4.10. A tie plate may also be used as a brace, as

view

B(3) of figure 4.10 shows. When manufactured rail braces are not

on hand, braces may be cut with a torch from rail sections. Then

they are spiked to the tie so that they bear against the web of the

rail. Such a brace is shown in the sketch at the right.

c.

As soon as a spring thaw occurs, shims must be removed, tie

plates must be

replaced, or ballast must be replaced, depending upon the method used to compensate

for heaved track. After that, the tracks must be resurfaced. The difficulty and expense of these operations are

major reasons for taking every possible step to correct the poor drainage leading to heaved track.

4.22.

CREW SAFETY AND COMFORT

For their safety and comfort, be sure that

maintenance crews wear warm clothing during

cold

weather and, in severe climates, provide shelters

for them at

suitable locations on the line. When using

snowplows,

make certain that personnel are clear of wings

and

108

Previous Page

Previous Page