3.15.

SIZE

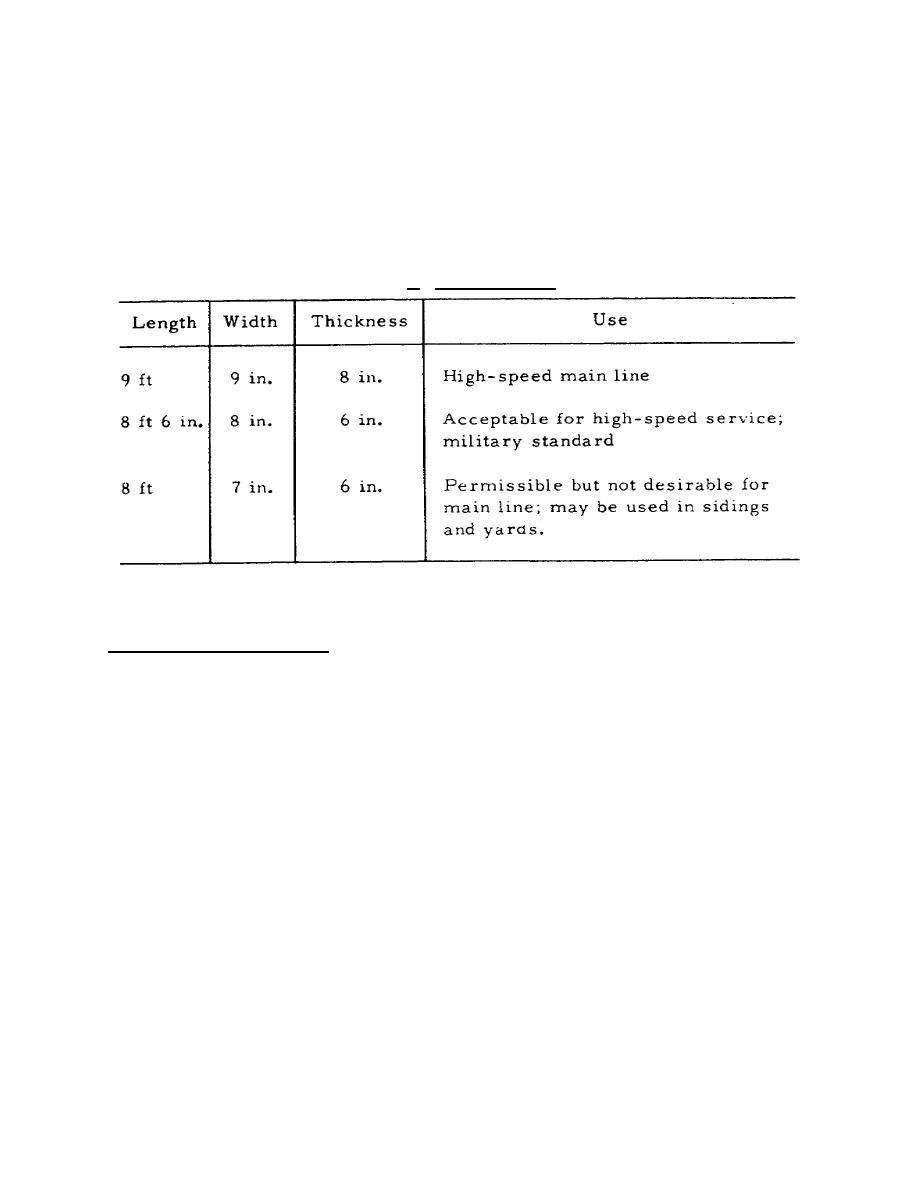

Recent trends in track construction have been toward larger and higher quality ties, not

only for more effectiveness in service but for economic reasons as well. For the rails to have

satisfactory support, a tie should approach 9 inches in width. Standard tie length in the United

States varies from 8 to 9 feet; tie thickness, from 6 to 7 inches. Given in table II are typical tie

sizes with recommended uses for each.

Table II. Typical Tie Sizes

Bridge ties are sized and spaced to conform with the design of the particular bridge. Ties

placed under switches are longer than standard ones. Switch tie size is discussed further in

Railway Track Maintenance II.

3.16.

SPACING

The number of ties per length of track depends on the volume, weight, and speed of the

traffic and on rail weight. The decision as to the number of ties per rail length depends upon

the space to be left between them, the length of unsupported rail. Experience shows that this

space should not exceed 18 inches. For case in manual tamping, the space should not be less

than 10 inches; for machine tamping, 8 inches is sufficient. On tangents, military engineers

prescribe spacing ties at 24-inch intervals, measured from the center of one tie to the center of

the next one; on curves and through tunnels, at 22-inch intervals.

One large commercial railroad specifies the spacing for ties given in table II.

52

Previous Page

Previous Page