similar in shape, we are able to draw several conclusions concerning their stiffness without going

into the true theory of the concept. The first conclusion is that for rails of similar shape, the one

with the greater height is stiffer. Secondly, since they are made of similar material, their weight

is proportional to their cross-sectional area. It is roughly true that rails vary in stiffness in direct

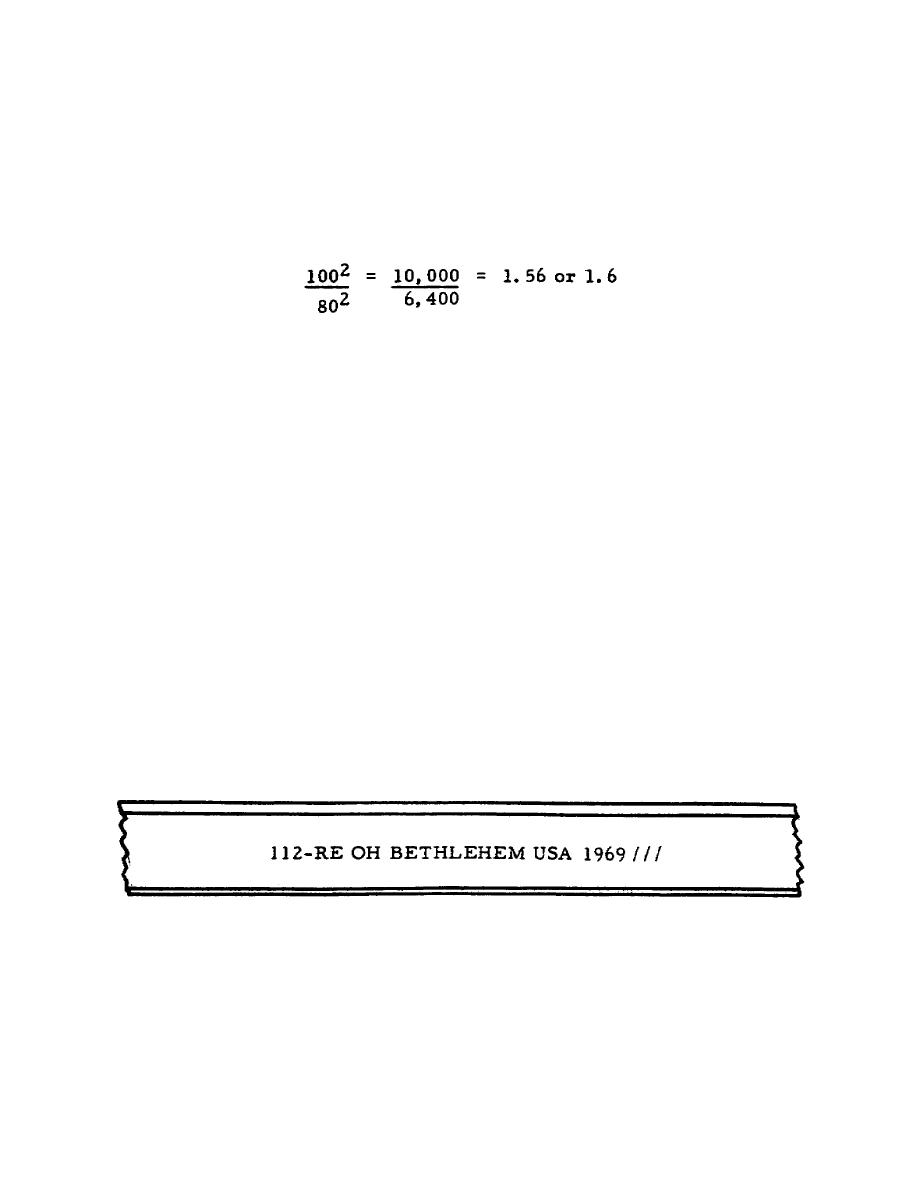

proportion to the square of their weight. Suppose you are comparing 100-and 80-pound rails.

Your equation would be--

Therefore, the 100-pound rail is 1.6 times stiffer than the 80-pound.

3.7.

SECTIONS

The several different types of rail sections in use vary in their capabilities and

characteristics. The subparagraphs following describe several types of rail sections; additional

data on them are given in table I.

The first standard rail sections were developed by the American Society of Civil

Engineers and are known as ASCE sections. Later the American Railway Association (ARA)

and the American Railway Engineering Association, jointly, improved on the designs with two

series of sections, RA-A and RA-B. The A series was meant for use in high-speed territory;

notice its height and thin head. The B series was designed for use in heavy curvature, grade, and

tonnage districts; notice its narrow, deep head for long rail life. Still later the American Railway

Engineering Association alone assumed the task of determining proper rail sections. The heavy

rails they developed became known as RE sections.

3.8.

MARKINGS

The story of a rail's manufacture is branded and stamped on its web. For instance, you

might find the following marking branded on a rail:

44

Previous Page

Previous Page