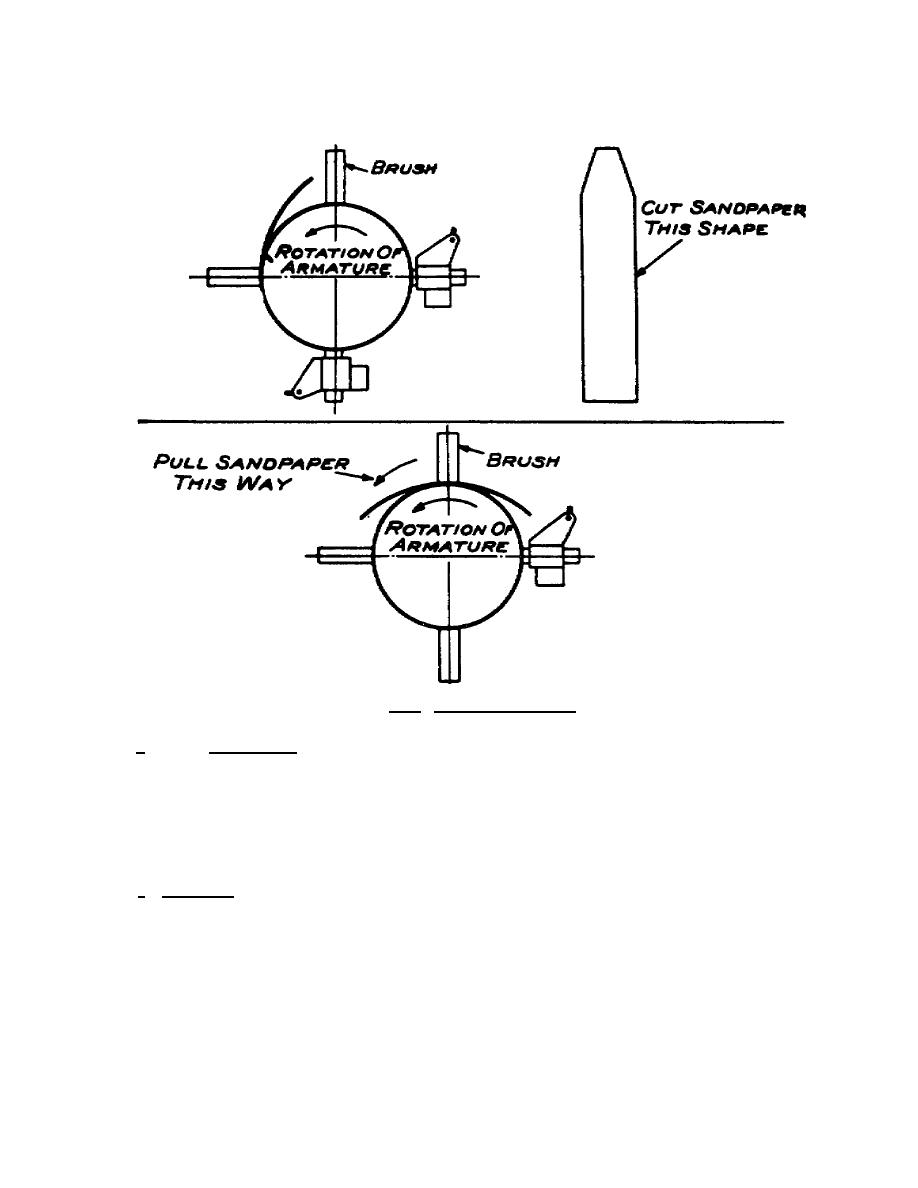

Figure 2.10. Sanding-in Brushes.

e. If the commutator becomes pitted, clean it with a fine commutator stone. The process is

shown in figure 2.11. Be careful to keep copper dust from the windings; after stoning, blow out the

windings with low-pressure compressed air. If the commutator has high and low spots or signs of

burning, place the armature in a lathe and turn the commutator enough to produce a uniform surface.

After the commutator has been turned, undercut the mica. Do not lubricate the commutator, but insulate

the commutator cap with insulating varnish.

f. Insulation may be dipped and baked if necessary, but it may need only a light spray coating of

insulating varnish. Avoid needless dipping and baking because extra material on the windings decreases

heat transfer and ventilation. Since insulation deteriorates in service, it is tested first to determine if

repairs are needed, then again after repairs are finished.

72

Previous Page

Previous Page