coupling toward the outer ends of the car. The buffer has a

housing, attached to the car, and a spring-loaded section

extending out of the housing. The coupling operation is

entirely manual.

To couple cars, the shackle of one screw coupler is

hooked over the hook on the other car; the lever tightens

the screw until all slack is taken up. Faces of the two

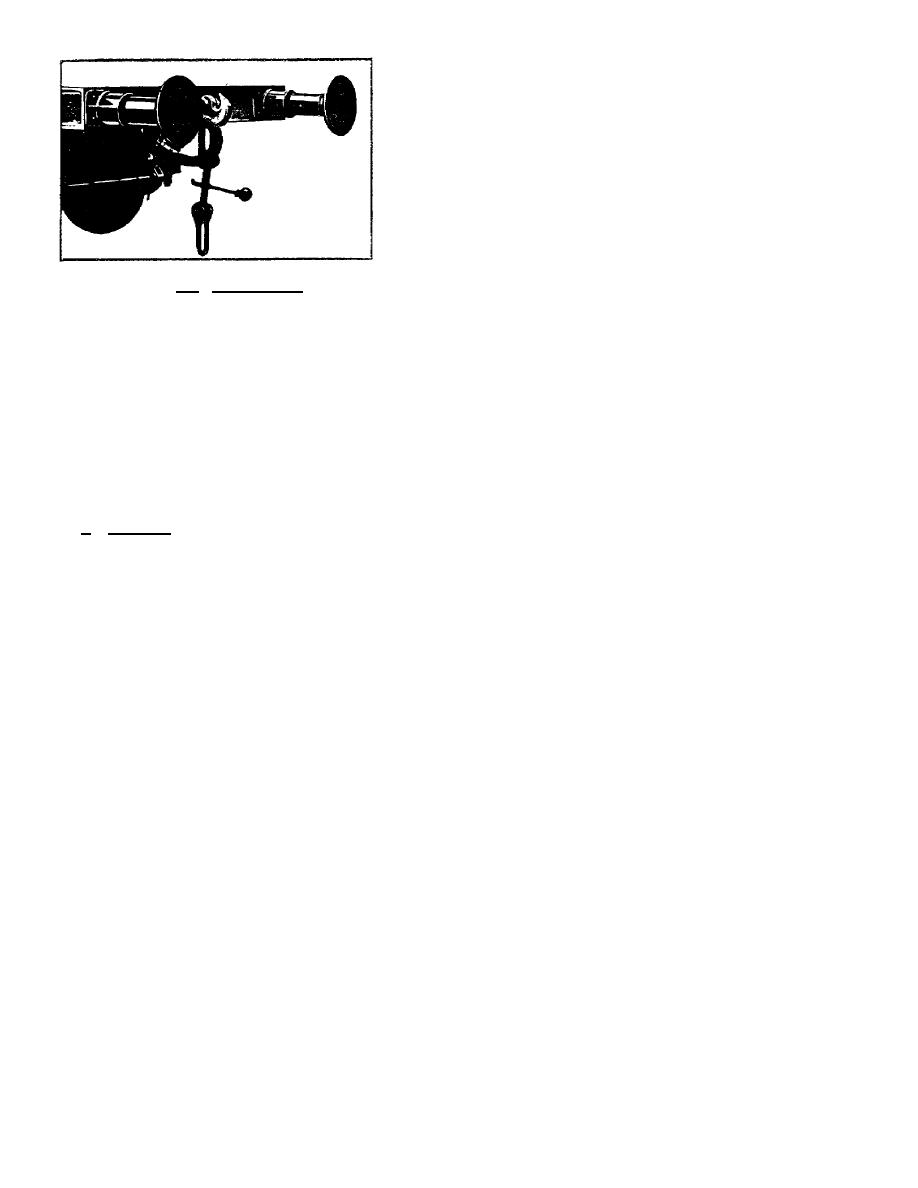

Figure 5.9. Side Buffers.

buffers on the one car should then be pushed squarely

against the faces of those on the other car. When the train starts or runs, the screw coupling carries the pulling

load; the buffers protect the cars and lading by absorbing jolts and shocks, and prevent cars from running

together--the function of the draft gear on U.S. equipment. To uncouple, the lever unloosens the screw until

there is enough slack to lift the shackle off the hook. Besides the danger to men working between the cars, this

type of coupling equipment makes switching a slow, time-consuming operation.

b. Willison. Working on the same general principles as the E coupler on U.S. equipment, the Willison

coupler has one marked difference: a transition device, shown in figure 5.10 as note six, makes it possible to

couple to the hook-and-link coupler. Although coupling is automatic like the E coupler, jolts and shocks are

absorbed by side buffers not by draft gear.

5.9. SUMMARY

Connecting the coupler to the car underframe, draft gear cushions the shock when cars are coupled

together or when train speed changes suddenly. Friction draft gear, found on most U.S. rolling stock, has a unit

of coil springs and a friction unit contained within a housing. As the springs compress, they push against the

plates and wedges of the friction unit, setting up resistance and permitting cars to start smoothly. Rubber draft

gear, used on locomotives, passenger cars, and some freight cars, offers the same resistance through a series of

rubber plates that absorb shocks during coupling.

71

Previous Page

Previous Page