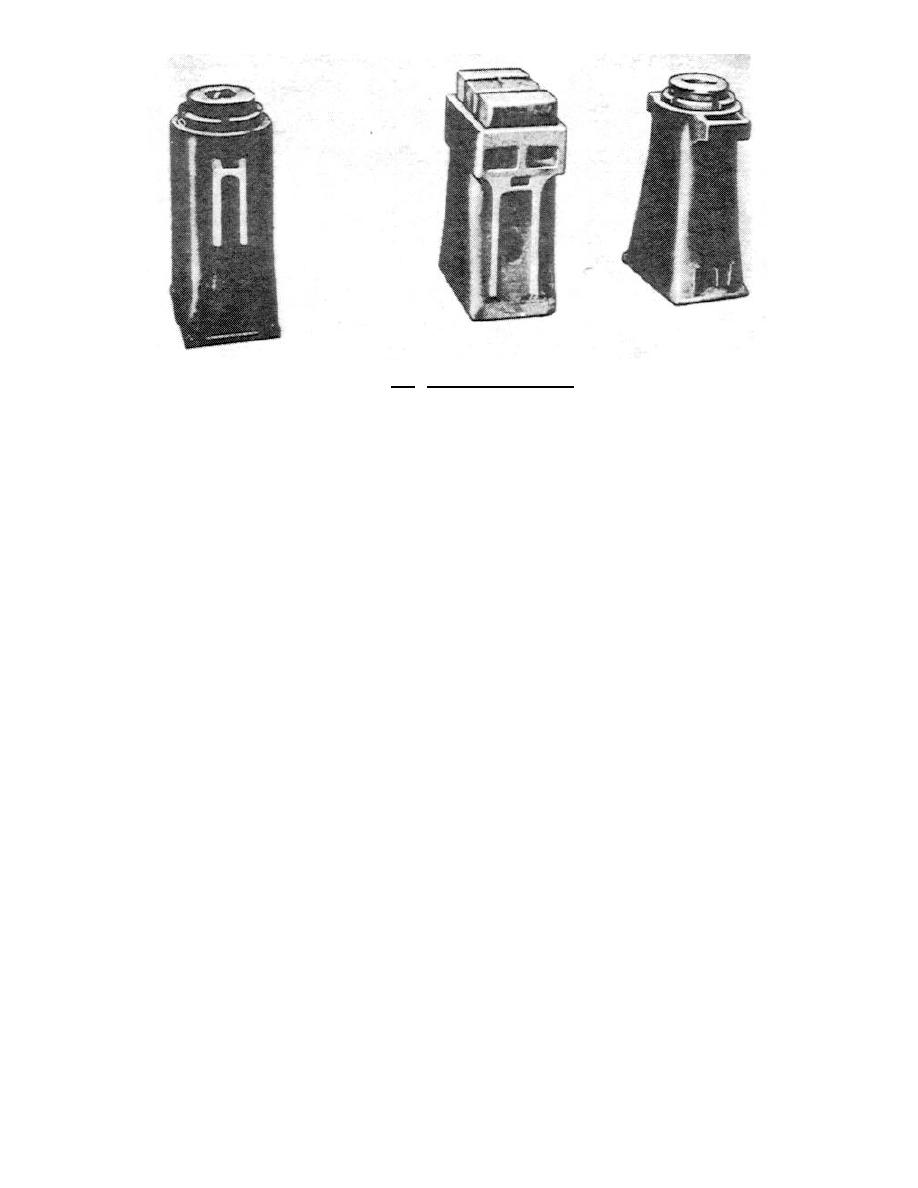

Figure 5.1. Friction Draft Gears.

within the housing of both there are coil springs and friction units made up of plates and wedges.

As the coil springs begin to compress, they meet the resistance of the friction unit. The more the springs

compress the harder they bear against the friction plates and thus the more the resistance to the compression

pressure. The resistance action permits cars to be started smoothly; when pressure is released, the friction unit

prevents the springs from recoiling too rapidly. A draft gear operates the same way when a car is suddenly

pushed rather than pulled.

5.4. RUBBER DRAFT GEAR

Designed to fit the standard draft gear pocket in the underframe, the rubber draft gear has been used on

locomotives and passenger cars for over 30 years. Its use on freight equipment is gradually becoming more

frequent. At present, rubber draft gear is found on the Army's diesel-electric locomotives, on cars in ambulance

trains, and on some troop and kitchen cars. The gear unit, as seen in figure 5.3, includes a series of rubber plates

that take care of shocks during coupling.

5.5. COUPLER

A coupler does three things: connects one car with another, holds the connection, and then disconnects the

two cars. Cars built in this country before 1933 were equipped with what was known as the

64

Previous Page

Previous Page