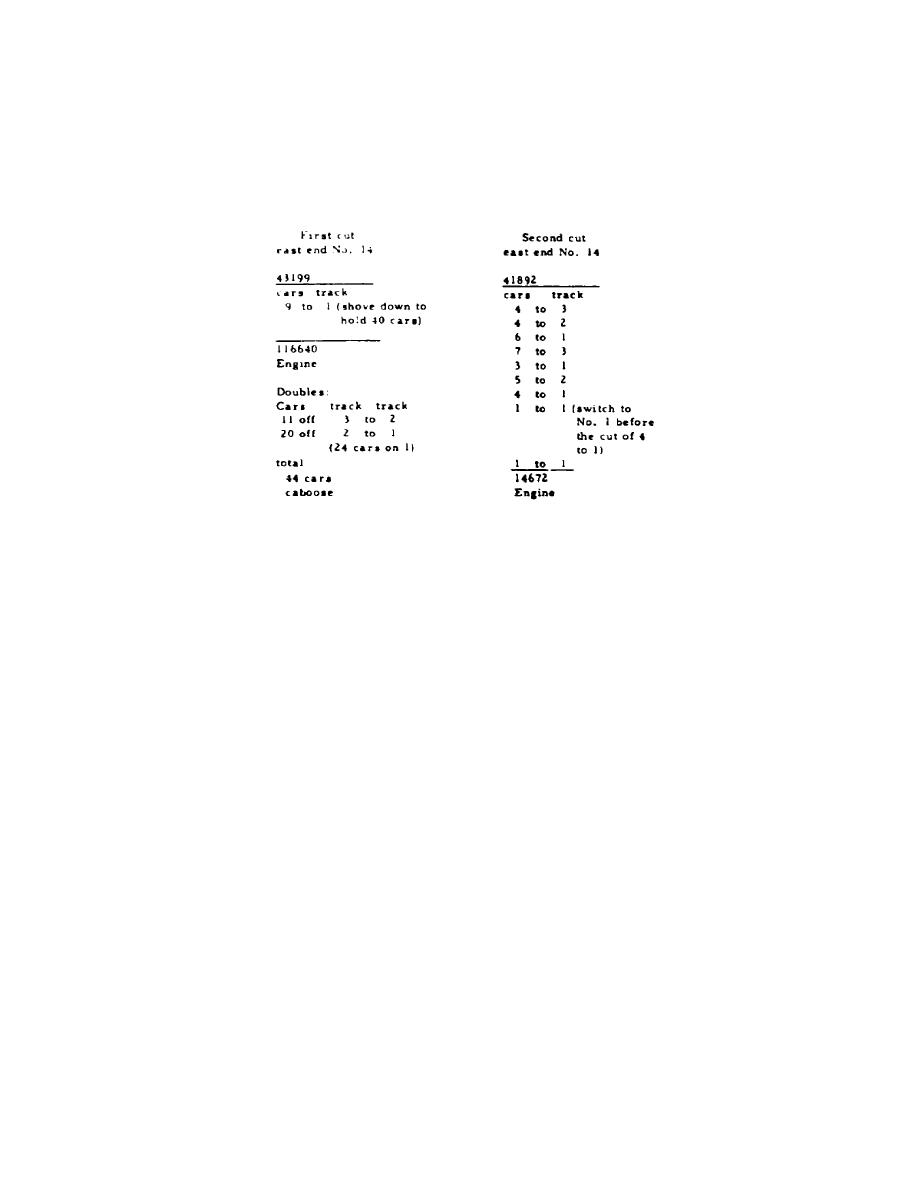

(2) Column II of figure 2.6 shows a slightly different method

of switching the track. While the switching operation is reduced by

only three cuts, the important saving of time is accomplished in

doubling the train together after switching. A switching list of the

method in column II of figure 2.6, showing full instructions to the

conductor, follows.

(3) A comparison of columns I and II of the check of track 14

back in figure 2.6 reveals that the yardmaster has saved cuts and

doubles principally by his marking of the cars 9 through 21, and by

the handling of the 35th car. With the saving of three cuts and five

doubles, an estimated 30 to 40 minutes have been saved. The saving

in time might even be greater if other crews were using the same

switching lead. Moreover, while making the doubles, the crew might

possibly delay other yard crews wanting to use the switching lead.

Since yard operations can cost a third of all rail transportation

expenses, the importance of eliminating delays is apparent.

2.15. SUMMARY

Receiving inbound trains, classifying cars according to

destination or commodity, and making up outbound trains are the main

jobs to be done in a railway yard. When a train is received into the

yard, inspectors go to work inspecting the cars for defects, making a

record of any cars needing repairs. A yard clerk makes a track check

showing the standing of cars in the train, from which a switch list

is made that shows the order in which the train is to be cut or

broken up and switched.

32

Previous Page

Previous Page