CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

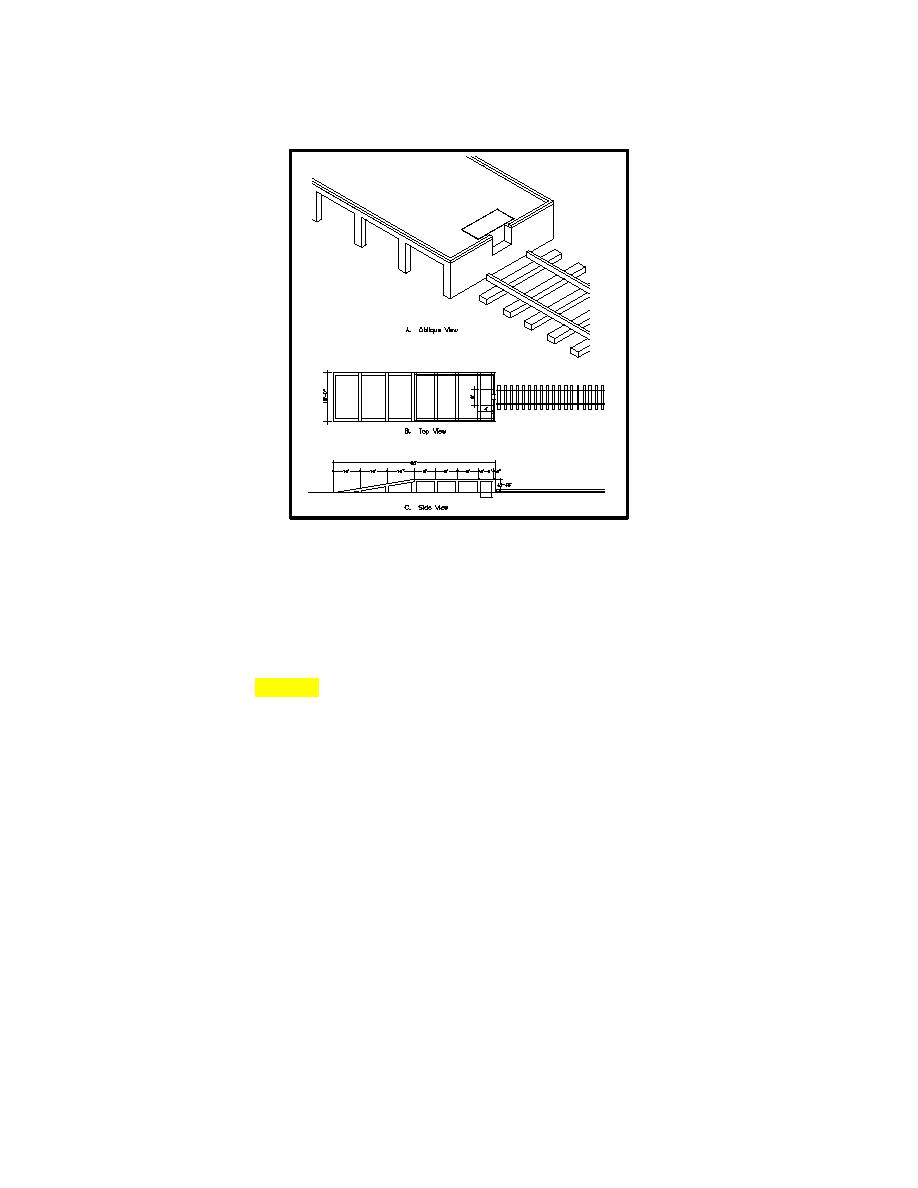

Figure 8-4. Concrete End Ramp

(4) To make vehicle loading easy, it is desirable to have the end of the car very close to the ramp

platform. It is also necessary to protect both the car and the ramp from impact damage when cars are

being positioned at the ramp. As car designs vary (draft gear length, amount of end overhang, position of

uncoupling lever, etc.), this protection cannot be reliably provided by fastening wheel stops to the track.

(5) The design in figure 8-4 incorporates a cut-out at the front of the ramp at the height of the car

coupler. Behind the cut-out is a concrete block separated from the remaining ramp structure with

cushioning (expansion joint) material. This concrete bumper block reduces the likelihood of impact

damage to the ramp.

(6) Other shock absorbing designs and devices can be used as well, including commercial railcar

buffers. The designer should select the method best suited for the particular application. While the

concrete bumper block could easily be incorporated into new construction, it might prove impractical

during rehabilitation if the existing ramp platform will not be extensively modified.

(7) To permit wheeled vehicles to cross the gap between the ramp and the flatcar, spanner boards

may be necessary; tracked vehicles do not require spanner boards. Thus, if fixed spanners are used,

they should be detachable so that they will not interfere with the loading and unloading of tracked

vehicles.

f. Multilevel Ramps for Smaller Wheeled Vehicles.

8-6

Previous Page

Previous Page