CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

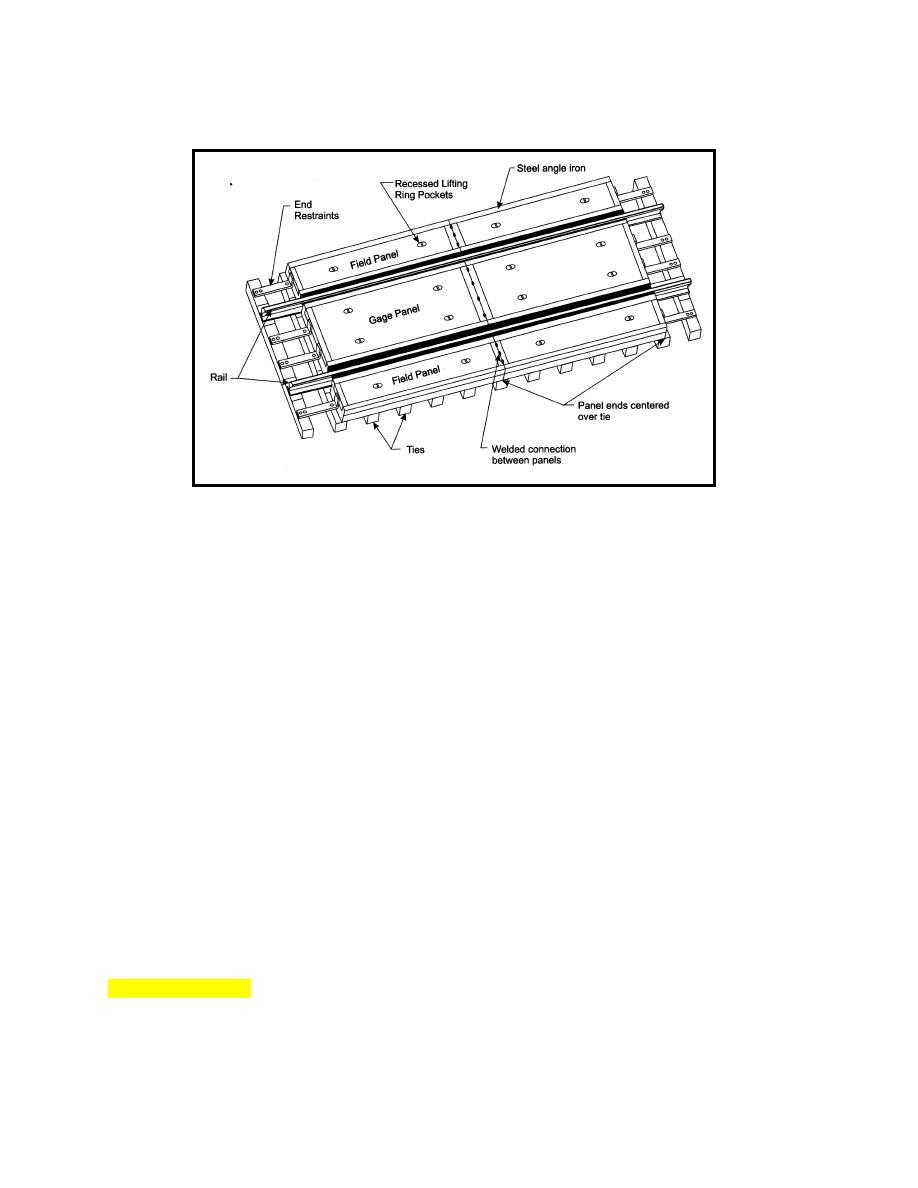

Figure 7-12. Lagless Concrete Panel Crossing

(15) Type 4C Sectional Monolithic Concrete (No Ties). These crossings essentially form a concrete

roadbed and crossing surface all in one complete unit. The rails rest on rubber pads in precast concrete

sections that form a solid bed. The concrete bed rests on a layer of crushed rock over a prepared

subgrade. These crossings may be well suited for rail service through an active container handling area

or where the track would normally run through a concrete paved area. They may also be warranted

where there is frequent heavy truck traffic and other crossing types have not withstood the traffic and

loadings. With these crossings, the rail is accessible by unbolting and removing the upper gage panels;

however, since the bed is solid, the track cannot be surfaced (tamped or raised) by conventional

methods. Surface correction or track raise must be done by either completely removing the crossing

sections and altering the subgrade, or for small corrections, by pressure injection of grout beneath the

sections. A subgrade and base material with adequate strength and drainage are essential for good long-

term performance of these crossings. These are the most expensive of the 10 crossing types

generally about twice the cost of a concrete panel (Type 4B) crossing.

(16) Type 5 Full Depth Rubber Crossing. Like the concrete panel crossings, these are made of

separate panels that rest on the ties and fit around the rails. Flangeway fillers are built into the panels.

While most are fastened to the ties with lags, some designs are available for a lagless installation.

Rubber crossings provide a flexible surface, but that flexibility prevents spreading heavier wheel loads

over a larger area and may lead to rutting in the tire paths where traffic is heavy. Snow plowing

operations can often damage rubber surfaces. The most durable are made completely from what is

termed "virgin" rubber. The other option - recycled or reconstituted rubber, is less expensive, but is not

suitable for larger traffic volumes or for heavy truck traffic.

e. Drainage. All crossings, for all surface types, require a subdrainage system similar to that shown in

figures 7-13 and 7-14. Geotextile surrounding the pipe filter is optional, but recommended in fine-particle

soils where clogging of the filter may occur.

7-16

Previous Page

Previous Page